Keeping a natural product natural with renewable energy and more …

By George Harvey

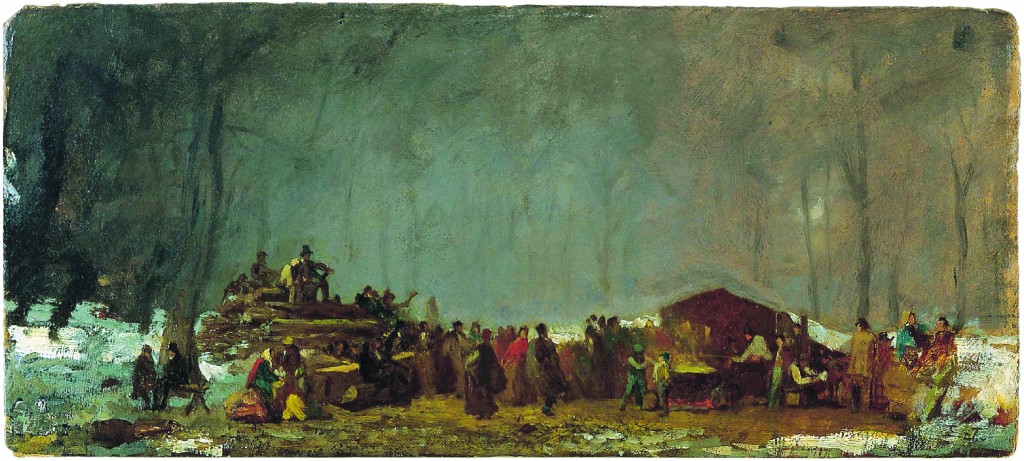

The Maple Sugaring Camp,” ca. 1870, by Eastman Johnson. In the 19th century, sugaring could be a community thing, with musicians sitting on the woodpile, and dancing near the fire. Public domain.

Old-time pictures of traditional maple sugaring are deeply ingrained in the minds of many of us, and not just those of us who grew up long ago in Vermont or New Hampshire. Covered buckets hanging from taps on trees, people trudging through the snow with buckets of sap, horse-drawn sledges with tanks, and open-air evaporators are all part of scenes many of us easily remember, even if they are from before our times. We know them from quaint photographs and paintings by such illustrators as Norman Rockwell, Grandma Moses, and Currier and Ives.

In those days, the work for the next year’s harvest started with cutting many cords of firewood to boil sap. It was an energy intensive operation, both in terms of human labor and in the quantity of wood. In the days before trucks and chainsaws, maple sugaring might have produced quaint pictures and fond memories, but it was not easy.

Through the years, maple-sugaring operations turned progressively toward methods that reduce labor. Oil has been used for fuel and gas-powered engines do much of the work.

Recently, however, standards have updated again. The predictable maple sugar producer’s love of the land has started to transform the industry to practices chosen for sustainability and low pollution. Today, some local operators have turned the corner, giving up on fossil fuels almost entirely, making them nearly 100% dependent on renewable resources.

Some maple sugaring operations have gone back to wood to fuel evaporators. But boiling sap is not the only process on the farm that takes a lot of power. Buildings need to be heated and powered with electricity, and vehicles need to be fueled. Turning from grid-powered electricity to solar is an obvious step. So is heating buildings without fossil fuels, and even going to bio-diesel for vehicles.

We were surprised to discover there is a lot being done in other areas we did not think of right off. A look at a few of the maple sugaring operations in Vermont and New Hampshire provides some great examples.

Solar Sweet Maple Farm

Solar Sweet Maple created a warm and inviting space where visitors sit at the farmer’s table for some refreshments — a perfect way to spend a spring afternoon.

Tom Gadhue had a vision, and it produced his motto, “A green twist on an old Vermont tradition”. He wanted to make maple syrup, and he wanted the farm to have the smallest environmental impact possible. So he and his wife, Rhonda built Solar Sweet Maple Farm to be as sustainable as possible.

He started building his sugarhouse by salvaging the frame of a glassblower’s studio. The siding was also salvaged from three area barns. The building was insulated with panels, four inches thick. The sugarhouse with a large, south-facing roof, so it could hold as many solar PVs as possible. His 12.5kW array is net-metered, so he can bank electricity credits in the summer for use in the winter.

Tom chose a number of energy-saving features as well. The lighting is all done with LEDs. The reverse-osmosis machinery he has removes 80% of the water before the sap is heated, and it is solar-powered. Vacuum pumps pull sap to the building, also powered by the sun. The evaporator is fueled with wood from his own woodlot. So is the hot water and heat for buildings.

Solar Sweet Maple Syrup is made in a 5×14 D&G wood-fired gasification evaporator. The wood is harvested from their sugar woods and is used to heat the evaporator and the sugarhouse.

The evaporator is powered by wood, but with a new twist. It has a wood gasification system that starts with a fire beneath the evaporator, captures unburned flu gasses, then adds fresh air to finish burning them , heating the evaporator more. This results in a burn that is as nearly complete and non-polluting as possible.

Heat is reclaimed from the steam as the sap boils. It is used to preheat sap for the evaporator. Tom estimates a reduction in the amount of wood needed to boil the sap of over 70%.

Solar Sweet Maple Farm has a line of maple products including four different grades of syrup, samples and gift items, maple cream, maple walnuts, and maple balsamic dressing.

The farm is located at 3841 South Lincoln Road Lincoln, Vermont. Their number is 802-453-6063 and the website is solarsweetmaplefarm.com.

Silloway Maple Farm

Silloway Maple, in Randolph Center Vermont, really does date back to the times of Norman Rockwell. Paul Silloway started it as a dairy farm in 1940 and expanded into maple sugaring in 1942. In those days firewood and sap were gathered with a team of horses, and no fossil fuels were used at all.

Today, the maple operation is managed by Paul Lambert, Paul Silloway’s grandson, with his mother Bette, and David, Lynne, Stuart, and John Silloway. The firewood for the evaporator comes from logging waste, but the amount needed is also reduced from what it was in the old days. Most of the water in the sap is removed before it is even heated up by using reverse osmosis. The reverse osmosis is powered by sunlight from the farm’s solar PV array.

Recently, the farm needed a new building for sugaring. Paul and Bette Lambert decided to put 17.5kW of solar PVs on its roof. The solar system was installed by Integrity LLC of Bethel, Vermont. This provides power for the farm’s maple sugaring with excess going towards the dairy production. The system is grid-tied and net-metered, so summer production helps with winter usage.

When the Vermont Agency of Agriculture started a voluntary sugarhouse certification program, Silloway quickly joined in to get one more seal of approval, cleanliness, and safety.

The farm has about 6100 maple trees and the owners hope to produce 3100 gallons of pure maple syrup. In addition to syrup, they produce maple cream and maple walnuts, peanuts and almonds. Their products are sold at the farm, in retail stores, and through their website. They also have a working dairy with 65 milking Holsteins. They do logging, and sell firewood.

Bette Lambert asked that we remind everyone that the Vermont Maple Open house Weekend is March 22 and 23. Silloway Maple Farm will, of course, be participating. She said they will offer maple sugar on snow and homemade doughnuts with syrup. How could anyone pass that by?

Silloway Maple Farm is at 1033 Boudro Road, Randolph Center, Vermont. Their number is 802-728-3625.

North Family Maple Farm

In earlier times, Shaker communities were divided into groups called families, often named after compass points. The North Family Maple Farm occupies land of the North Family of the Shaker community in Canterbury, New Hampshire, settled in 1792.

The farm has been a family-run business since 1950. Today, it is run by Tim, Daimon, and Gemini Meeh and Jill McCullough. In 2011, they won an award as New Hampshire’s outstanding tree farm for 50 years of sustainable forest management.

Starting as a dairy farm, in 1959, it became a school, which eventually moved to its own campus. Farming started again in 1974, and since then, the farm has produced a variety of products. It has had a small retail Jersey dairy, and bred and trained Percheron horses. It has had grain crops, and organic vegetables. It has sold milling lumber.

Now, the farm sells hay, firewood, timber, and maple products, all grown with an eye to sustainability. It has a small wind turbine and 7kW of owner-installed solar PVs. It uses biodiesel and sustainably grown wood for fuel. Unsurprisingly, their maple product is New Hampshire Certified Organic Maple Syrup.

The farm uses reverse osmosis to concentrate the sap. Then a gasification system evaporator removes most of the remaining water. This reduces the amount of firewood needed by 87%.

Their website also provides some very interesting information on the health benefits of maple syrup, including its effectiveness against diabetes and certain common types of cancer. There are links to information sources.

The maple products include maple syrup in various sizes and container types, maple cream, and maple sugar.

North Family Farm is in Canterbury, New Hampshire. The number is 603-783-4712, and the website is northfamilyfarm.com.

Leave a Reply